In the chemical, pharmaceutical, food, and biotechnology industries, mixing and homogenizing liquids are critical processes. The use of conventional motors with shafts and mechanical seals can often lead to problems such as leaks, contamination, reduced service life, and lack of scheduled maintenance.

To solve these problems, a new generation of motors has been developed: magnetic drive motors . These devices use a magnetic field to transmit torque, eliminating the need for shafts and direct mechanical seals, thus ensuring greater safety, cleanliness, and efficiency.

The operating principle of a magnetic motor

The design of a magnetic motor is based on torque transmission through non-mechanical contact. In this system:

-

The motor contains a series of permanent magnets or electromagnets.

-

Another set of magnets is attached to the part of the housing that corresponds to the impeller.

-

When the motor starts to rotate, the resulting magnetic field causes the internal components to move, which in turn causes the impeller to rotate.

This design eliminates the physical connection between the motor and fan, and torque is transmitted solely by magnetic force . This construction completely eliminates leaks and eliminates the need for mechanical seals.

Advantages of magnetic motors

-

Leakage and contamination protection:

Since there are no columns running through the cavity, the liquid remains completely enclosed in the reservoir. This feature is crucial in the pharmaceutical, biotech, and food industries. -

Reduced and simplified maintenance costs:

The absence of mechanical seals and internal bearings reduces the risk of failure and the need for regular maintenance. -

High safety for toxic and corrosive liquids

In applications involving hazardous, toxic or highly corrosive liquids, the use of a magnetic actuator reduces the risk of leaks and damage to the operator or the environment. -

Longer equipment life

: Reduced mechanical friction and wear on parts extend the life of the machine and improve productivity in the long term. -

Sterile processing.

In the pharmaceutical and biotech industries, a sterile environment is critical. These mixers feature an insulated, sealed design and are sterilizable in place (SIP) and steam-processable.

Hydrodynamics and performance

From a hydrodynamic perspective, the performance of a magnetic motor is of utmost importance. Its main characteristics are:

-

Flow pattern : These motors can have impellers that produce axial, radial, or mixed flow. The choice of impeller type depends on the process objectives (uniformity, heat transfer, particle suspension, etc.).

-

Mixing density : Through direct and indirect torque transmission, these mixers can generate high shear rates and increase the mixing density.

-

Precise speed control : Most magnetic motors are controlled by a variable frequency drive (VFD), which enables precise speed control and process dynamics control.

-

Scalability : These motors can be used on both laboratory and industrial scales while maintaining the same dynamic principle.

Application of the magnetic motor

1. Pharmaceutical and biotechnology industry

A sterile, contamination-free environment is critical for the production of drugs, vaccines, cell culture media, and recombinant proteins. Magnetic storage devices are the ideal choice for these applications.

2. Food and beverage industry

Magnetic drives are used in the production of dairy products, juices, food additives and aseptic products to maintain quality and avoid contamination.

3. Chemical and petrochemical industry

These motors improve safety when working with corrosive or toxic materials such as acids or certain solvents.

4. Cosmetics and health industry

When manufacturing creams, lotions, and contamination-sensitive products, the use of an isolation mixer is crucial.

5. Semiconductor and electronics industry

When manufacturing high-purity chemicals for the electronics industry, any impurity can affect the quality of the product.

Problems and limitations

Although magnetic motors have many advantages, they also have limitations :

-

Torque transmission limitations: Magnetic torque transmission has lower strength than a straight shaft and may not be suitable for applications requiring very high strength.

-

High initial cost : Due to the advanced technology and special materials, the price of these faucets is higher than that of mechanical models.

-

Temperature sensitivity : Permanent magnets can lose their magnetic properties at high temperatures , so choosing the right material for a specific application is crucial.

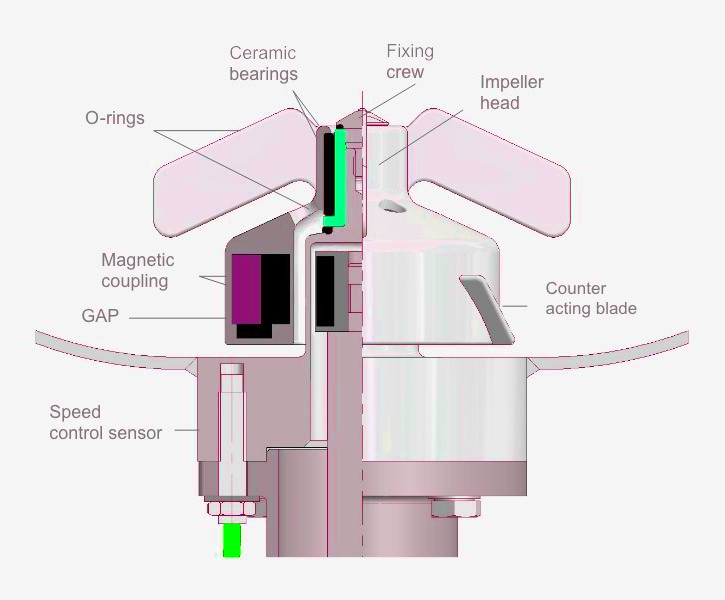

Design and main components

-

Electric motor : provides the main driving force.

-

Magnetic coupling : consists of permanent magnets or electromagnetic elements that transmit the torque.

-

Sealed lid: prevents leakage and completely isolates the interior from the outside environment.

-

Impeller – depending on the process, it can be axial, radial or compound.

-

Control systems : speed and torque control , process status monitoring.

The future and innovation of magnetic motors

With technological advances, these devices are becoming increasingly intelligent and efficient. New trends include:

-

Uses stronger and more heat-resistant neodymium magnets .

-

The intelligent motor monitors temperature, pressure and viscosity in real time.

-

Improved design for lower energy consumption and improved mixing uniformity.

-

Suitable for microplates and small-scale biological applications.

Finally

Magnetically coupled electric motors are an innovative and efficient solution for industries prone to leaks, contamination, and high maintenance costs. By eliminating the need for mechanical seals, these devices offer increased safety, long service life, and improved efficiency in a wide range of processes. Despite

the initial costs and limitations in power transmission, they remain an excellent choice for sterile, sensitive, and isolated applications. Thanks to new technology trends, the use of these electric motors is expected to spread across more and more industries in the coming years.